Services

Professionalism + Quality

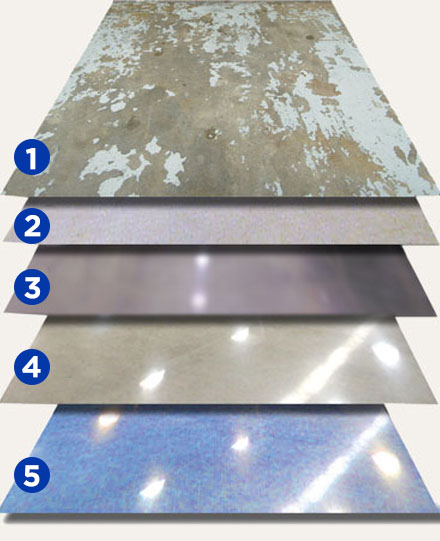

Our Process

1)

Floor Prep: removal of coatings: paint, sealers, wax, etc.

2)

Metal Cuts: floor is ground smooth using metal bond diamond-pads.

3)

Densification: chemical densifier is added to strengthen and dustproof the floor, as well as increase scratch and abrasion resistance.

4)

Polishing Cut: Resin bond diamond pads polish the floor to the desired level of shine and reflection

5)

Color: an option to dye the floor to the customer’s liking is also available.

About Polished Concrete

More retail, restaurant, warehouse, fleet management and office facilities are opting for polished concrete flooring as an alternative to marble, granite, tile, vct, wood, linoleum, or coated concrete. Even homeowners are catching on to the appeal of these smooth, high-luster floors, which can be stained to replicate the look of polished stone.

Elegant and Attractive

Looks amazing & professional. It can be dyed to match any color scheme. Polished Concrete, much like marble, never goes out of style.

Very Strong and Durable

Extremely tough and resistant, and is able to withstand the pressure and weight from heavy equipment. Surface cannot be easily scratched.

Less Maintenance

Polished Concrete requires minimal maintenance and is very easy to clean. No more extensive scrubbing or constant refinishing with wax.

Extended Long Life Span

Properly maintained polished concrete floor can last years. Refurbish needs a fraction of the cost of other systems, extending the life much farther.

Highly Cost Effective

Most polished concrete floor installations are quite cost-effective. The savings are even more significant if you factor in maintenance costs over lifetime .

Hygiene Friendly

Properly polished concrete can be virtually resistant to fluids, providing waterproof barriers to prevent contaminants from getting to the concrete.

Minimum Downtime

Polished concrete areas can be put into service immediately after process is complete. It can also be installed while the facility is still in full production.

Better Ambient Lighting

The High light reflectivity is another important benefit, especially for office, stores, restaurants etc., to project a bright, clean, professional image.